SAP APO (Advanced Planner and Optimizer)

Definition or Meaning - What is SAP APO (Advanced Planner and Optimizer)?

Full form or SAP APO stands for (Advanced Planner and Optimizer), an innovatively designed and smartly packaged planning and optimization tool, is a fast becoming an indispensible component of supply chain processes.

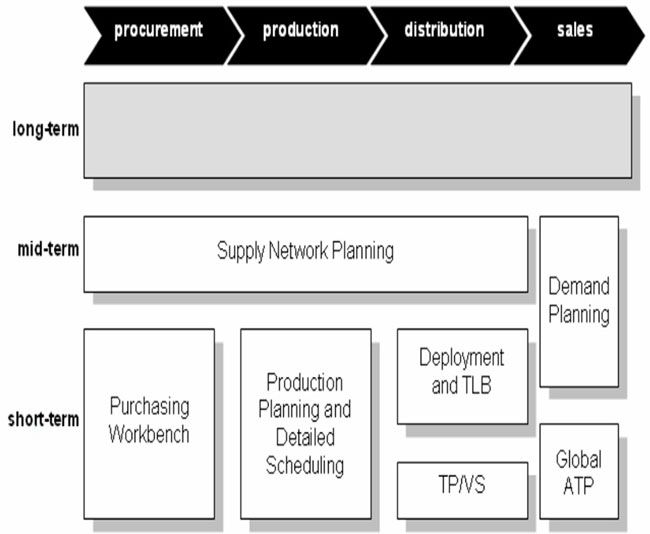

The 8 application levels of APO are:

- Network design

- Demand planning

- Supply network planning

- Detailed scheduling and production planning

- Global availability,

- Vehicle scheduling and transportation planning and

- Supply chain management

This popular SAP application is packed with diverse in-built features and functionalities. It taps into real-time updates from retailers and others in the supply chain and offers accurate information in regards to customer demands. These updates generate "demand triggers" that address the productions cycles and delivery schedules to perfection; thus forecasting the right product quantity that an organization would need to cater to future customer demands.

SAP APO is integrated with SAP SCM and has helped companies customize the tasks of supply chain management to a large extent.

Functionalities of APO

APO offers:

- End-to-end business processes and planning of inventory.

- Collaborations with customers and suppliers through Supply Network Collaboration (SNC) or Inventory Collation Hub (ICH).

- Spare parts management with SCM 5.0 and other associated applications.

- Tight integration to execution (OLTP) systems like ERP with standard interfaces known as Core Interface Function.

Scope and Opportunity of a Career in SAP APO

Boasting of a heavy market demand, SAP APO certification paves the way for plenty of opportunities and higher paying jobs. Chennai, Kolkata and Noida are some of the hotspots for SAP APO jobs. They include the positions of senior consultants, chief managers, associate managers as well as entry level consultants.

Out of 10000 software professionals in India, 8 have an expertise in SAP APO. The demand for this subject is increasing on a daily basis and freshers are getting their due share of attention in this field. Bristlecone, Infosys, Mind tree and IBM are some of the companies looking for freshers as well as professionals in SAP APO.

An average package of 5.38 lac p.a awaits newcomers in this industry. Here, the top paying companies are IBM, ITC info and Accenture. Experienced personnel having 7+ years of experience can expect salaries in the range of 11.6 to 38 lac p.a.; along with an average rate of 13 percent of employee bonus after an additional year of experience

Become a Certified APO Consultant

Specifically built for project leaders, project members and analysts working with supply chain processes and demand planning applications, APO courses help in improving the skills of schedule planning, demand planning, pricing, supply network management and so forth.

To pursue a course in APO, an individual must possess:

- A university degree in one of the specialized fields: MSc, MCA, BE, Bsc, ME, MBA, etc.

- Sound knowledge pertaining to business processes, logistics and supply chain management.

- An awareness of SDAP and ERP tools.

- Basic knowledge of information technology and basic computer terminology.

- Good communication and time management skills.

APO applications sit at the heart of SCM and are readily integrated with Enterprise Resource Planning (ERP) and SAP R/3 systems. Join up and take your career to newer levels of success –today!

SAP APO certification opens gateway of opportunities towards high paid jobs. In India the places that offer good salaries are Calcutta, Chennai and Noida. The job profiles are of SAP APO consultant, senior consultant, Associate manager and chief manager.

8 out of 10,000 professionals in India have expertization in SAP APO. The demand is increasing and thus freshers are also getting huge attention in this field. The companies that look for freshers are Infosys, Mind tree, Bristlecone and IBM. The average package a fresher gets is about 5.38 l p.a

The top paying companies are IBM, Accenture, and ITC infotech. Experienced personnel with about 7+ years of experience can fetch salaries from the range of 11.6 to 38 lac p.a. the companies pay an average rate of 13% of bonuses to its employees after the additional year of experience.

Read Next:

SAP APO (Advanced Planner and Optimizer) Certification Cost and Course Duration in India

Tutorials

- SAP APO (Advanced Planner and Optimizer) Certification Cost and Course Duration in India

SAP APO Courses & Certification FeesCandidates desirous of pursuing the SAP APO (Advanced Planner and Optimizer) course can contact reputed institutes across the country. The duration of this cour ... - How to Copy a complete APO system

You want to copy a complete APO system with all its master data and transaction data from one installation (source system) to another installation (target system). If the source system is connected t ... - SNP: Standard Methods of Safety Stock Planning

This note explains the standard safety stock planning methods: SB, SZ, SM, MB, MZ, and MM within Supply Network Planning. 1. Introduction Safety stock is used to safeguard supply chain inventor ...  SAP SCM - APO GATP

SAP SCM - APO GATP

SAP APO Global ATP What we will cover… Global ATP / OLTP Interface CIF Integration Model Rule-based ATP Elements of a Rule Product substitution procedure Loca ...- How to copy a Process Chain?

To copy a process chain to another process chain, goto the Process Chain you want to copy and then type copy in the tool tar and hit enter. It will allow you to copy the Process Chain to another Proce ... - CIF error Open SQL-Array-Insert leads to duplicate records.

This error is caused by the CIF transfer of material versions. For material versions to be transferred correctly from the R/3 into an APO system, the R/3 table MATERIALID must be mapped in APO tables ... - SNP heuristic and creation of purchase requisitions

I have got a question about the behaviour of the SNP heuristic in relation to the creation of purchase requisitions (PR's). 1) I plan both in daily and monthly buckets in the heuristic planning bo ... - How to Fix the Errors While Running Consistency Checks?

Hello Experts,Can anyone help me with some notes on consistency related to DP and how to fix the errors while running consistency checks? Firstly what or how many are there and how to fix them?Kindly ...