What is Batch Number?

A Batch Number is a unique identifier assigned to a specific quantity of a material that has been produced or received during a certain period of time. It is used to trace and manage materials in the supply chain from the point of production or receipt to the point of consumption or shipment.

A Batch Number can be used to track various attributes of a material, such as production date, expiration date, quality characteristics, and storage location. By assigning a Batch Number to a material, it becomes possible to perform batch-specific functions such as tracking, inventory management, quality control, and recall management.

When the Batch Number is Assigned in SAP?

A batch number is typically assigned when a material is produced, received, or issued from inventory. The batch number is then recorded in the material master record and used to track the material throughout the supply chain.

Advantge of Batch Number in SAP MM

Batch numbers provide several advantages in managing materials in SAP:

- Traceability: Batch numbers provide a way to trace materials throughout the supply chain, from production or receipt to consumption or shipment. This makes it easier to identify and track specific batches of materials in case of quality issues, recalls, or other issues.

- Quality control: By assigning a batch number to a material, you can track and manage its quality characteristics such as the manufacturing date, expiration date, and other relevant information. This helps ensure that materials meet the required quality standards and comply with regulatory requirements.

- Inventory management: Batch numbers provide a way to manage inventory more effectively, by tracking the quantity of materials in each batch and their respective locations. This helps prevent overstocking, understocking, and stockouts, and enables better planning and forecasting.

- Recall management: In case of quality issues or safety concerns, batch numbers provide a way to quickly identify and recall specific batches of materials from the supply chain. This helps prevent the spread of contaminated or defective materials and protect consumers.

How to Find Batch Number for Material in SAP

Please follow the step below to find the batch number for the material in SAP:

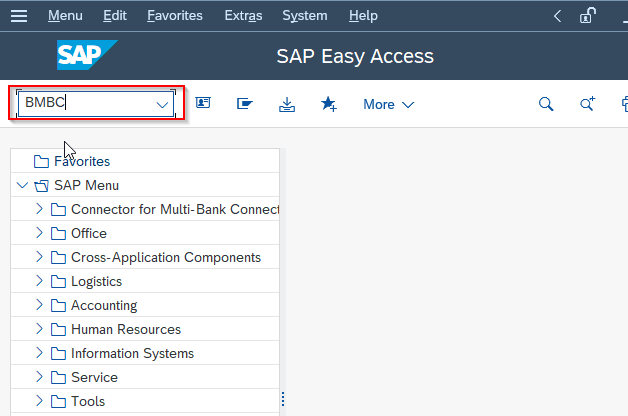

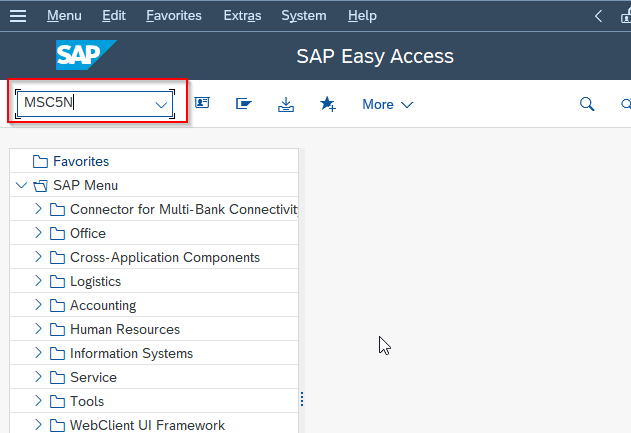

Enter the t-code BMBC in the SAP command field and press Enter to execute it.

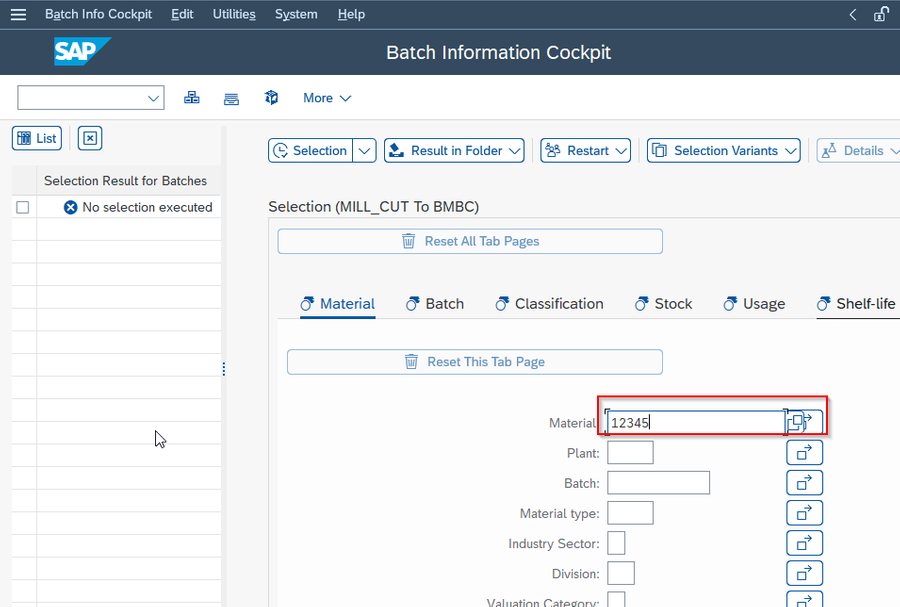

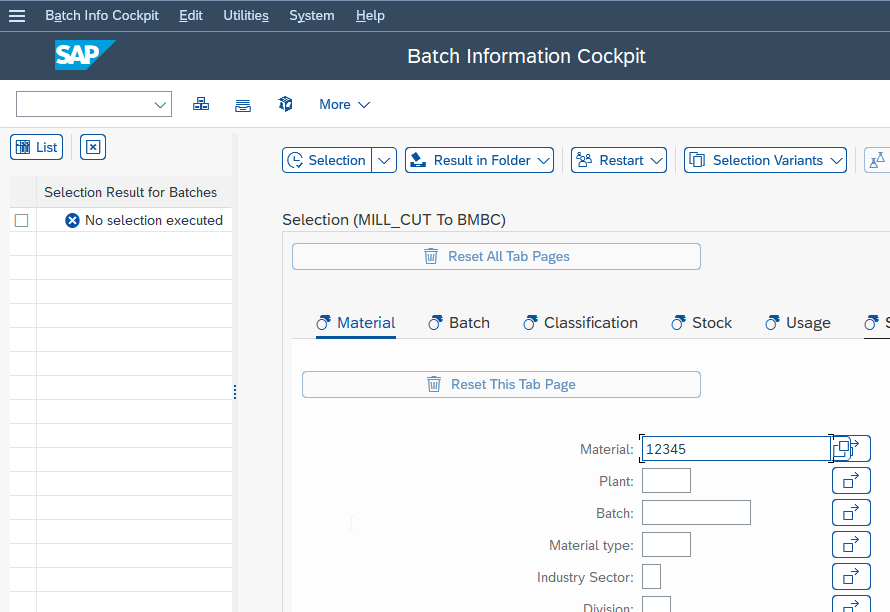

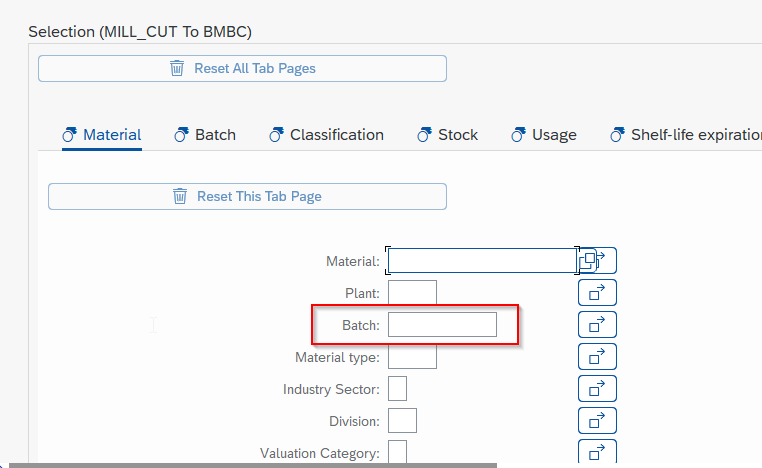

Next on the Batch Information Cockpit screen, enter the Material Number for which you want to find the Batch Number.

Select the Plant and Storage location for the material if applicable.

If the Batch Number is known, then enter it in the Batch field. If you do not know the Batch Number, leave this field blank to search for all batches for the material.

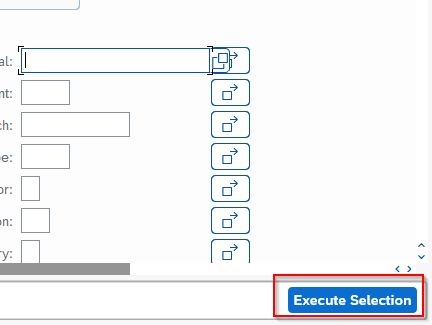

Now click on the Execute Selection button to run the report.

The system will display a list of all batches for the material, including the Batch Number, the quantity of the material in the batch, the manufacturing and expiration date, etc.

Note: The user can also filter the search results by various criteria such as the manufacturing date, expiration date, or the status of the batch.

SAP Batch Number T-codes

Other useful Batch Number T-codes are:

| T-code | Description | Functional Area |

| OMCZ | Activate batch number allocation | LO - Batches |

| OMAD | Number Ranges for batch numbers | LO - Batches |

| MM01 | Create Material & | LO - Material Master |

| MM02 | Change Material & | LO - Material Master |

| MIGO | Goods Movement | MM - Inventory Management |

| MMBE | Stock Overview | LO - Material Master |

| CT04 | Characteristics | CA - Characteristics |

| SE38 | ABAP Editor | BC - ABAP Editor |

| SE16 | Data Browser | BC - Workbench Utilities |

| MB1B | Transfer Posting | MM - Inventory Management |

| MSC2N | Changing batch | LO - Batches |

| MCHA | RIS: Till Receipt/Matl - Selection | LO - Retail Information System (RIS) |

| MCH1 | RIS: Execute Evaluation | LO - Retail Information System (RIS) |

| VCH1 | Create batch Search Strategy | SD - Conditions |

| MIRO | Enter Incoming Invoice | MM - Invoice Verification |

| SM37 | Overview of job selection | BC - Background Processing |

| VA01 | Create Sales Order | SD - Sales |

| SM35 | batch Input Monitoring | BC - UI Services, Screen, Batch Input |

| SM36 | Schedule Background Job | BC - Background Processing |

| PA30 | Maintain HR Master Data | PA - Personnel Administration |

| VF01 | Create Billing Document | SD - Billing |

| FERT | The flow of cost trace | FI - Financial Accounting |

| MSC3N | Display batch | LO - Batches |

| VL02N | Change Outbound Delivery | LE - Shipping |

| VL01N | Creating Outbound Dlv. with Order Ref. | LE - Shipping |

| MSC1N | Create batch | LO - Batches |

| MBC1 | Create MM batch Search Strategy | LO - Batches |

| CU70 | Create Sort Sequence | LO - Variant Configuration |

| MB1A | Goods Withdrawal | MM - Inventory Management |

| MM03 | Display Material & | LO - Material Master |

| SHDB | batch Input Transaction Recorder | BC - UI Services, Screen, Batch Input |

| MCHB | RIS: Till Receipt - Selection | LO - Retail Information System (RIS) |

| OPL8 | Order type parameters: Overview | PP - Order Planning |

| FBN1 | Accounting Document Number Ranges | FI - Financial Accounting |

| CL02 | Classes | CA - Classes |

| SE11 | ABAP Dictionary Maintenance | BC - Dictionary Maintenance |

| CL01 | Creating a Class | CA - Classes |

| MMNR | Define Material Master number Ranges | LO - Material Master |

| VN01 | number Assignment for SD Documents | SD - Sales |

| OMCG | Search Procedures: batch Determ. MM | MM - Inventory Management |

| BMBC | batch Information Cockpit | LO - Batches |

| COB1 | Creating a batch search strategy - prod. | LO - Batches |

| OIS2 | Maintaining serial number profile | PM - Plant Maintenance |

| OMCV | Classify batches | MM - Inventory Management |

| OMCT | batch Definition | MM - Inventory Management |

| SNUM | Number Range Driver | BC - Number Range Management |

| SM30 | Call View Maintenance | BC - Table Maintenance Tool |

| SE37 | ABAP Function Modules | BC - Function Builder |

| SNRO | number Range Objects | BC - Number Range Management |

Question

I have a batch number with no material number. There is no more inventory with this batch number. How can I find out the material that this batch number was assigned to?

Answer

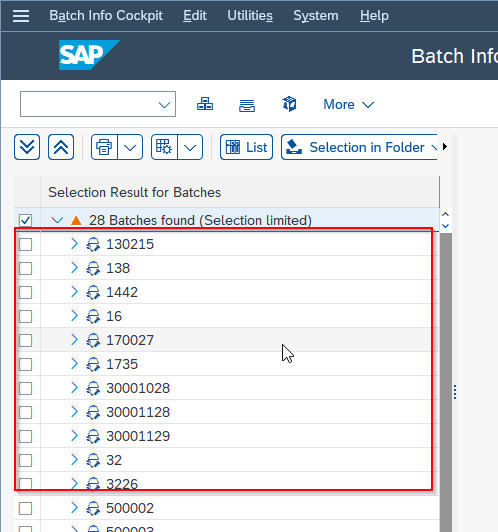

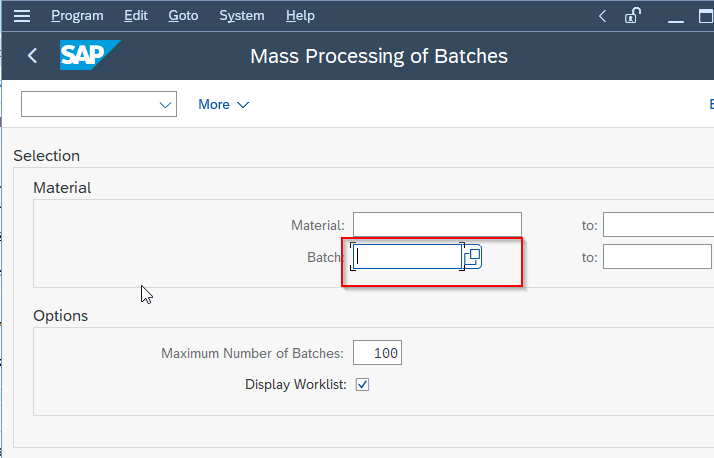

Execute t-code MSC5N in SAP Command field.

Next just enter the batch no as shown in the image below.

Now press Execute button to find out material number that is assigned to that batch.